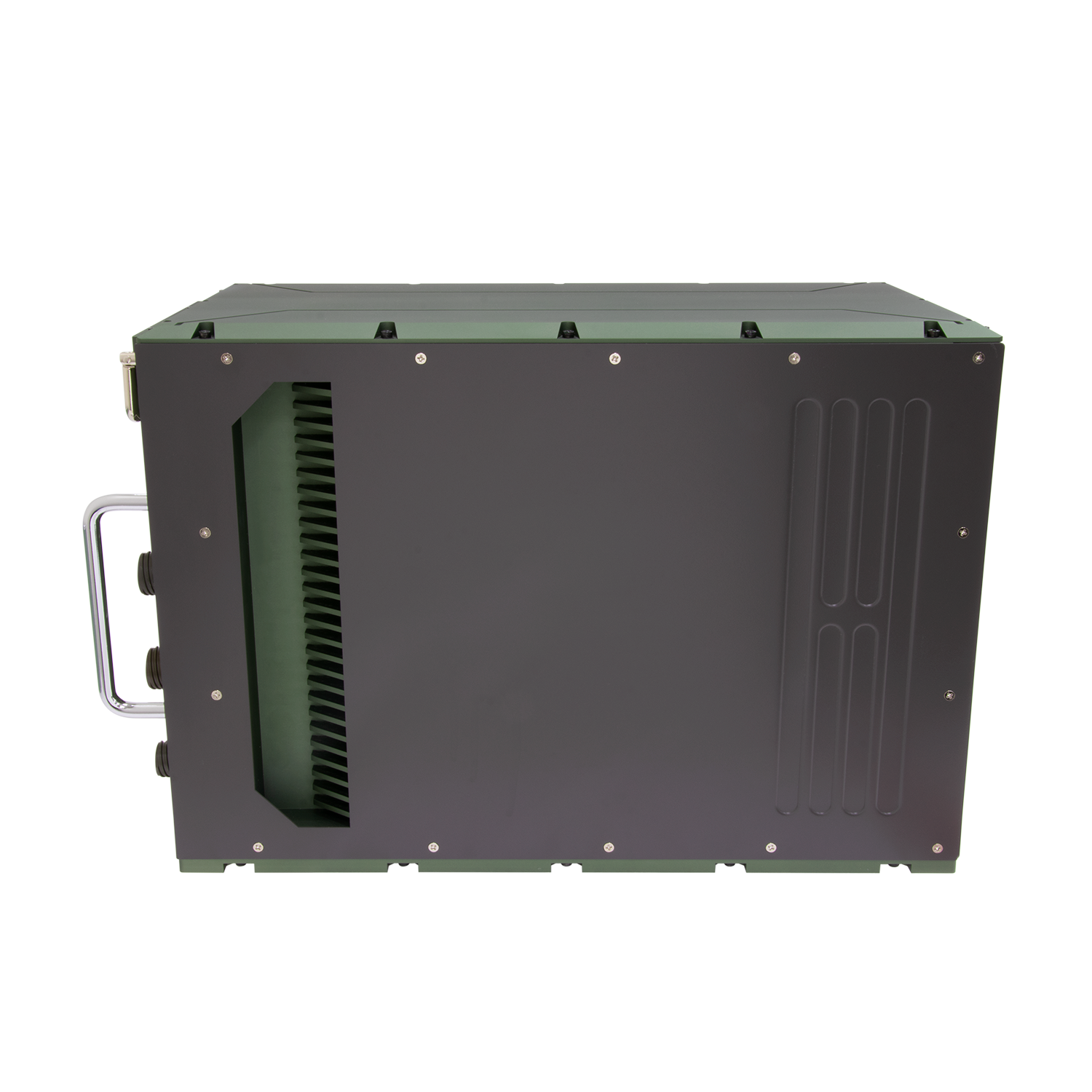

Description

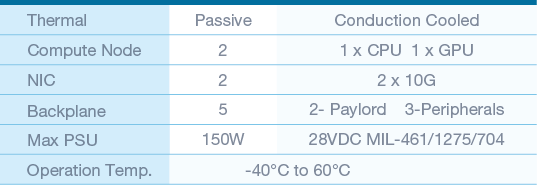

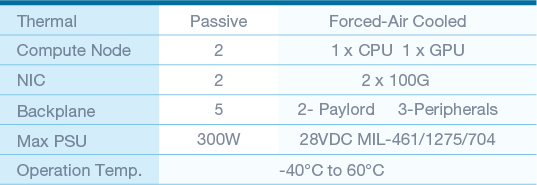

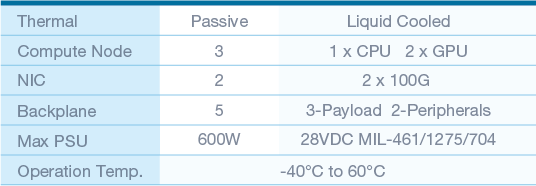

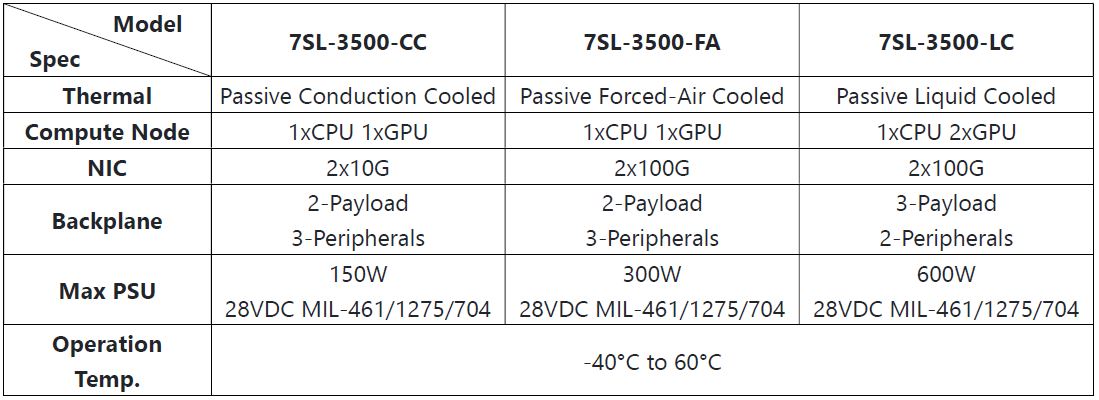

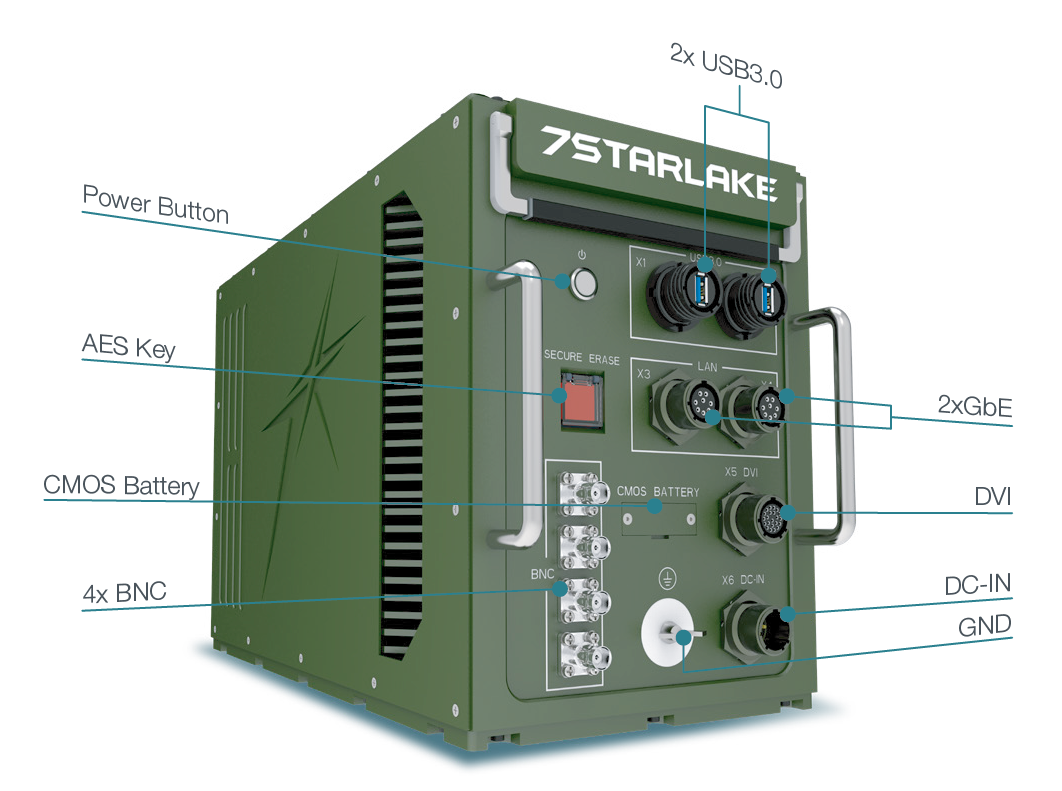

The 7SL-3500 VPX System is a modular Military Rugged ATR enclosure, geared for 3U OpenVPX designs. The versatile design allows multiple customizable configurations based on proven components and design techniques. 7SL-3500 Hybrid conduction cold plate assisted by forced air sets with aggregate power demands over 300W, assisted by liquid up to 600W. Custom and standard 5 to 6 slot backplanes with VPX and SOSA aligned slot profiles in combinations supporting high speed signal processing applications. Scalable to multi CPU-GPU-FPGA requirements Designed expressly for Gen 4.0 ultra-high wattage military systems.

7StarLake scalable and customizable, rugged VPX ATR System enables compute-intensive, SWaP constrained mission-critical applications for deployment in the world’s most demanding military and aerospace environments.