Description

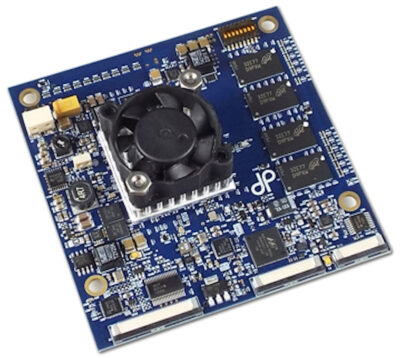

Spinosaurus LX EVO is a highly customizable and user-programmable FPGA-based highspeed smart cameras, is a high-end FPGA camera with a Xilinx Zynq FPGA and highspeed imaging sensor and a 10 Gigabit Ethernet. It includes high-performance ARM System-on-Chip (SoC) technology combined with turbocharged industrial LUXIMA imaging sensors.

With high-performance FPGA System-on-Chip (SoC) technology, Spinosaurus LX EVO camera opens new dimensions in computer vision. It is a global shutter industrial camera with incredible frame rates and an open FPGA architecture. With its FPGA processing power the image processing algorithms can run in real-time on the camera. Spinosaurus LX EVO includes a fully customizable and user-programmable openreference design for its high-speed FPGA-based camera and application development system. Its emphasis is on an open hardware/software development model, high-frame rates, realtime image processing on FPGA and modern graphical user interface support on the PC side.

A suite of versatile and high-performance tools for Xilinx Zynq Ultrascale+ SoC FPGA is used to develop algorithms and process data in realtime. Images are acquired by Luxima LUX2810 sensors with 32x LVDS interface (29 Gbps) achieving brilliant images at a very high speed. The on-board 2GB LPDDR4 memory with 19 GB/s of bandwidth enables usage of complex buffered image processing.

The reference design can be easily edited with standard Xilinx Vivado tools. OptoMotive´s custom IP cores seamlessly integrate inside the Xilinx Vivado toolchain. A large portion of FPGA (PL) is free for the programming and development of new algorithms, or the implementation of additional IP cores. The 1.2 GHz Quad Core ARM Cortex A53 Programmable Subsystem runs Linux OS with custom made EVO control and streaming stack (including Zero-copy TCP/IP stack). The SoC also includes dual 600MHz Cortex R5 processors which are free for user data processing. User applications or custom data post-processing can easily be added to the existing design.

APPLICATIONS:

- Laser triangulation- with a ready-made Peak detector on-board image processing core;

- Motion capture – with a ready-made BLOB detector or Running Length Encoder (RLE) on-board image processing core;

- Industrial process automation – to count, detect, check, verify, read, inspect and test different products, levels, components, etc. at an incredible speed;

- Industrial quality control – to inspect defects, cracks or surface blemishes, size, position, dimension and colour, foreign objects or quality

- General R&D.