Description

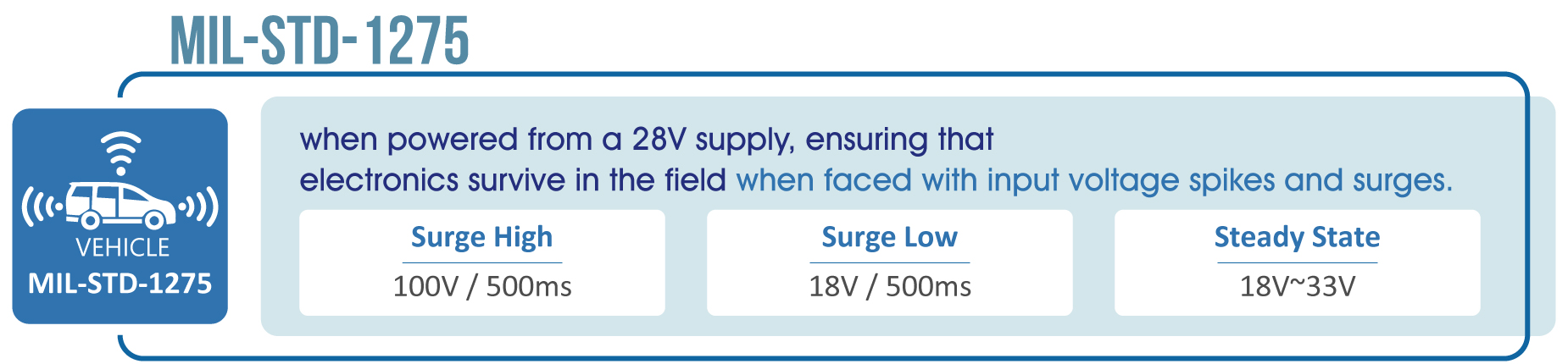

THOR100-X11 is driven by Intel 11th generation Tiger Lake-up3 i7-1185G7E processor soldering onboard which is an extremely compact Core I-based fanless rugged system. Tiger Lake-up3 processor supports outstanding CPU and graphics performance, providing quad cores 4.4GHz clock speed while consuming low power consumption 12W and Max. 28W. THOR100-X11 highlight on its rugged design and high functionality, the system especially installed MIL-STD Amphenol type but a D38999 mini DP connector and full IP65 protection allow system withstand in any kind of harsh environment. THOR100-X11 supports extended temperature from -40 to 70°C and wide range 8V~24V DC input can protect system from damages caused by sudden surge of voltage, thus further secure the reliability of its critical components and the system itself.

Robust Product Design Ready For Military Application

CPU

The THOR100-X11 offers highly effectively heat conductive and heat convective thermal solutions to meet the demands of customers’ extended temperature requirements. The heat conductive solutions uses an aluminum flat mass to place in direct contact with the processor and chipset, the heat from chips then transfers it to the case of the system. In addition, the convective thermal solutions introduce airflow directed to move across the surface of a fin style heatsink placed on top of the processor and chipset. This can be done with the aid of an appropriately sized fan placed in top of the fin style heatsink. Alternately, enclosure airflow can be routed to flow across a fin style heatsink.

Thermal Solution

7STARLAKE implements unique cooling solution with copper heat spreader, pure copper heat pipe and aluminum heat sink for maximum heat dissipation. With the aluminum heat sink enclosure allows dual-sided heat dissipation. We especially adopt the physical property of copper and aluminum, the copper heat spreader touches the heat source – processor to absorbs the heat rapidly, the heat then transfer to heat pipe; heat pipe is two-phase heat transfer involves the liquid-vapor phase change of a working fluid, the aluminum heat sink dissipates the heat into surrounding air promptly. With the benefits of fanless design, THOR100-X11 can ensure high reliability and stability while working under wide range temperature from -40°C to 70°C.